The manufacturing is for Proxima the strength of the business, because it creates the real added value to the products.

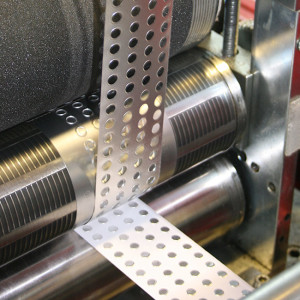

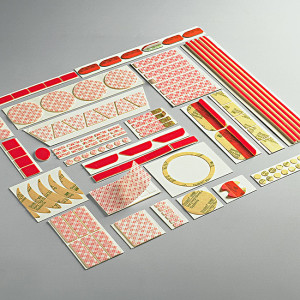

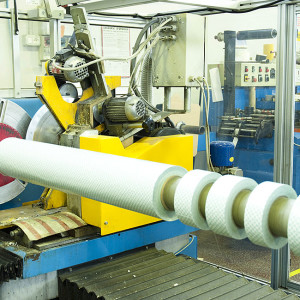

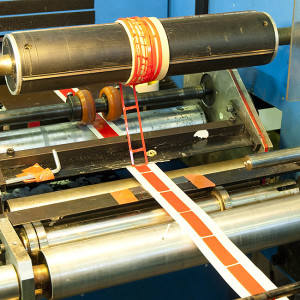

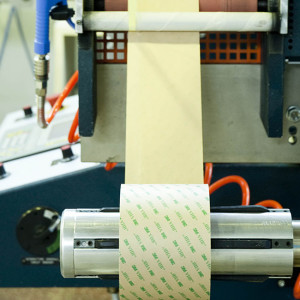

In addition to the product, in fact, Proxima is able to supply any article on specific request of the customer. The processing of tapes is in fact the solution often proposed and adopted by customers which would like to save time and money. Proxima has got the newest and most technological installations, specifically two rotary die cutting machines with digital control of new generation, two die cutting flat, two lathes size tapes, a calendar, a cutting and rewinding machine, two printing machines for adhesive ribbons, a Polyester Thermal label printer transfer and two slitters. Many of the plants have been modified and customized for specific manufacturing requests, thus creating a knowledge of the chances of transformation at the forefront. The supplied machines allow us to deliver the tapes die-cut in the form of rolls or on individual sheets, with holes or cuts on the liner.

The high-tech lathes cut the rolls with decimal tolerances so that the customer can have the tape width more congenial saving time and costs. The personalized cutting, in fact, has become a standard requirement for those working with tapes and, thanks to the added value of the cutting, use conditions are significantly improved, in fact you no longer have to adapt your products to the standard measures imposed by the producers, being instead able to manage rolls of a predetermined width, slaughtering costs of removal operations of any scraps in excess, increasing costs efficiency and saving material raw. Proxima is also able to make adhesive different supports, coupling with the most suitable adhesive the different types of of materials provided by the customers, fabrics, plastic films, gaskets, plates, profiles and anything else you need. Last but not least the adhesive ribbons and labels printing, introduced in production in the recent years but of strategic importance, allow us to provide a complete service to our customer.

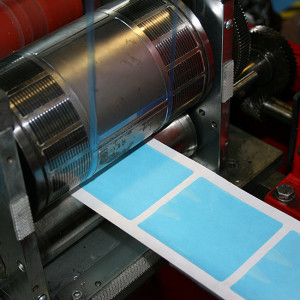

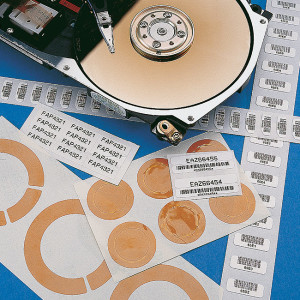

The printing machines are able to customize different adhesive, from protective tapes, aluminium, plastic films and the most known tapes for packaging. The press after cutting of the labels is under constant development, and today is the most popular technology in the permanent and safe identification of the products, which is certainly a key point for the current industrial world. So whatever you need in terms of customization of the products, you just have to ask us and our engineers will study with you the best solution to save time and of course money.